Description

1- Dough Fork Mixer

Bread is the staple food in the Middle East, Europe and Indian cultures. Main bread ingredients consists of flour (wheat or corn or barley), water, salt and yeast often. Sometimes bread contains some sugar, fruits and spices (such as raisins, pumpkin and bananas), vegetables (such as onions), and nuts. There are many ways to prepare bread and those ways vary from one community to another. In many parts of the world bread is hand made the way just old bakers used to do it, whereas in industrialized countries, most of the bread-making processes in commercial bakeries are mediated by machines such as fork mixers.

2- Dough Divider

Pies dough divider is used to divide dough into dough balls. The dough weight differs based on purpose and demand. It consists of aluminum extruding spiral shaft that is compatible with food grade policy. It is relatively silent in-operation. It is a mobilized unit that can be moved from one location to another.

3- Dough Flattener

Pies dough flattener is used to flatten the divided dough into circular dough plates. It flattens from 10-30 cm or 10-40cm with a thickness that ranges from 2-7 mm due to demand. It consists of hard chromate cylinders that are compatible with food grade policy. It is relatively silent in-operation. It is a mobilized unit that can be moved from one location to another.

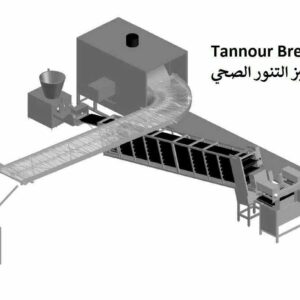

4- Multipurpose Pies Oven

Manakish is mostly known in Lebanon, Syria, Jordan and Palestine. They are kinds of pastries.

The ovens are designed after extensive studies and researches. They are found in different models, shapes and sizes due to demand: stainless steel or bricked, functions on gas piped burner, diesel burner or charcoal.

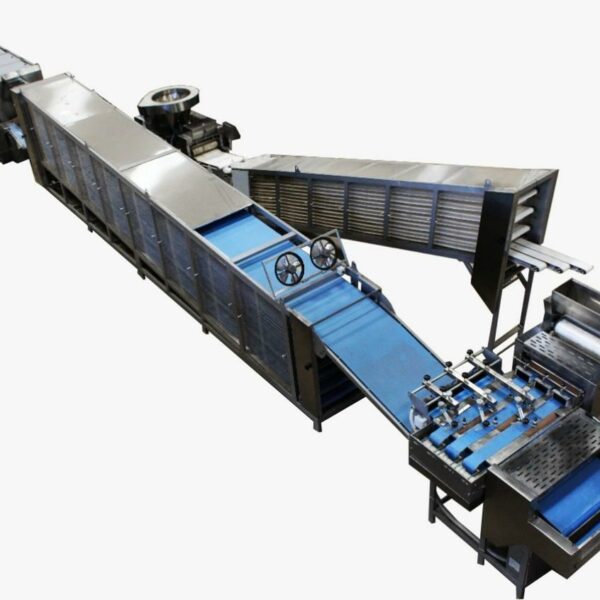

5- Compact Semi-Automatic Pies Line

This line produces various types of oriental pies (lahmajouin, thyme manakish, cheese manakish, pizza, etc.).

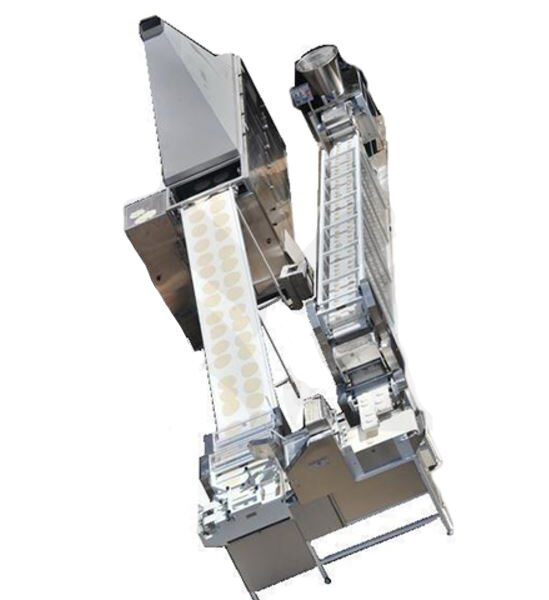

6- Smart Machine

The Smart machine is an automatic line for pies works via electro pneumatic system.

It consists of three stages:

• 1st stage – dividing dough from 40-180 grams

• 2nd stage: flattening the dough elliptically with thickness from 2 to 7 mm.

• 3rd stage: flattening the dough circularly from 15-40 cm due to demand.

This smart machine has a dough hopper at the divider side which handles 15 kg dough in-addition to one flour sifter at the flattener side. This smart machine is specialized in increasing the production speed and needs only one worker to operate it.