Description

Water extracted from water wells is treated with sea water RO, then specific amounts of sugar are dissolved into it. Next, it passes through filter sheets to ensure complete purity and quality, and finally mixed with the concentrates to create the final syrup.

The final syrup is then pumped through stainless steel pipes to both CAN and PET mixers, and mixed with water and CO2. After having the quality department ensure every step and product of every production phase meets the required standards, the beverage is sent to the filler to undergo the filling process.

Dry Mint (50g)

Dry Mint (50g)  Egg-plant Dip 370 gr x 24

Egg-plant Dip 370 gr x 24  Fig Jam (800g)

Fig Jam (800g)  Clementine Syrup

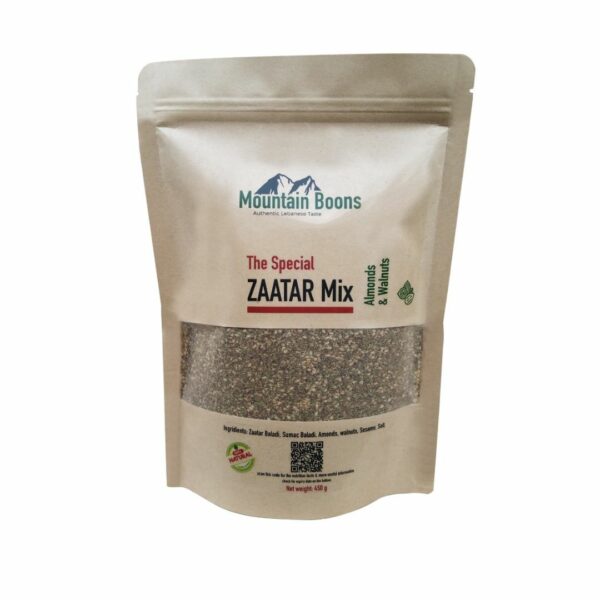

Clementine Syrup  Organic Zaatar Traditonal...

Organic Zaatar Traditonal...  Pomegranate Molasses (250ml)

Pomegranate Molasses (250ml)  Al Rabih Cherry Jam

Al Rabih Cherry Jam  Milk Chocolate Bar (100g)

Milk Chocolate Bar (100g)  Domo Vanilla Sugar 5G*3

Domo Vanilla Sugar 5G*3  Grape Molasses

Grape Molasses